Contact Engineering Services

Energy, Environment, Digitalization and Beyond !

Energy, Environment, Digitalization and Beyond !

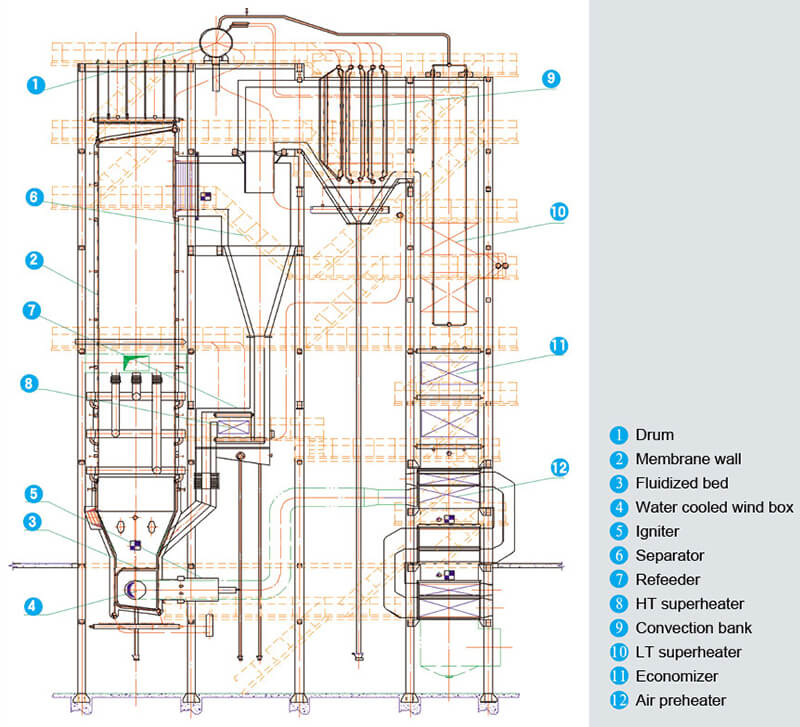

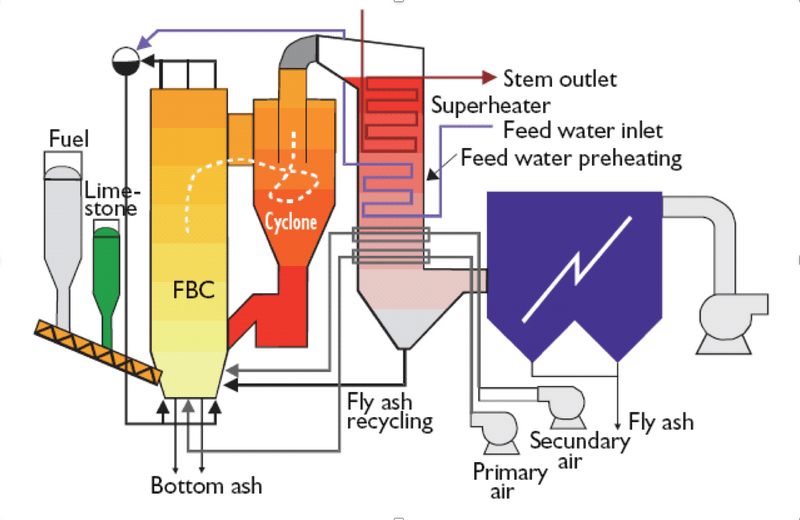

CFBC, as an alternative to pulverised coal combustion (PCC), uses a fluidised bed, an apparatus that mixes coal and air with a sorbent such as limestone during the combustion process, to facilitate more effective chemical reactions and heat transfer. In a fluidised-bed combustor, combustion occurs when the mixture of fuel, a sorbent and fuel ash particles is suspended by using a continuous stream of primary combustion air to create turbulence in the bed. The gas cushion between the solids allows the particles to move freely, giving the bed a liquid-like (fluidised) characteristic. CFBC technology offers several benefits. CFBC boilers are extremely flexible, allowing a wide range of fuel qualities and sizes to be burnt. Emissions of SOx and NOx are significantly reduced without the addition of expensive flue gas emissions control systems. This is due to the fact that the combustion temperature in a CFBC boiler (800–900ºC) is significantly lower than in a PCC boiler (1300–1700ºC), which results in considerably reduced NOx formation compared to PCC. The majority of the sulphur in the coal is captured by limestone that is injected into the furnace; about 90% to 95% SO2 reduction can be achieved. The lower combustion temperature also limits ash fouling and corrosion of heat transfer surfaces allowing the CFBC to handle fuels that are difficult to burn in a PCC boiler. Even though the combustion temperature of a CFBC boiler is low, the circulation of hot particles provides efficient heat transfer to the furnace walls and allows a longer residence time for combustion and limestone reaction. This results in good combustion efficiencies, comparable to PCC boilers. One of the disadvantages of the technology is that NOx and SOx emissions may exceed current stringent standards in some areas when the boilers are operated at less than full load. Further, the nature and impacts of CFBC residues (primarily ash) are not fully understood and therefore their disposal requires careful consideration.

CFBC technology is well suited to burn low grade and/or difficult to burn fuels. Many existing CFBC units are fired with waste coal and serve to clean up waste piles left over from mining activities, turning low/zero waste coal to valuable electricity. CFBC technology has been employed for power generation for over 25 years and the technology is still evolving. Almost all of the existing CFBC power generating units are small in size (330 MWe compared to >1000 MWe for a PCC boiler), and use subcritical steam conditions that makes CFBC systems less efficient than supercritical/ultra-supercritical PCC plants. The poorer economy of scale and lower efficiency of the CFBC plants result in higher plant costs and has limited its deployment.

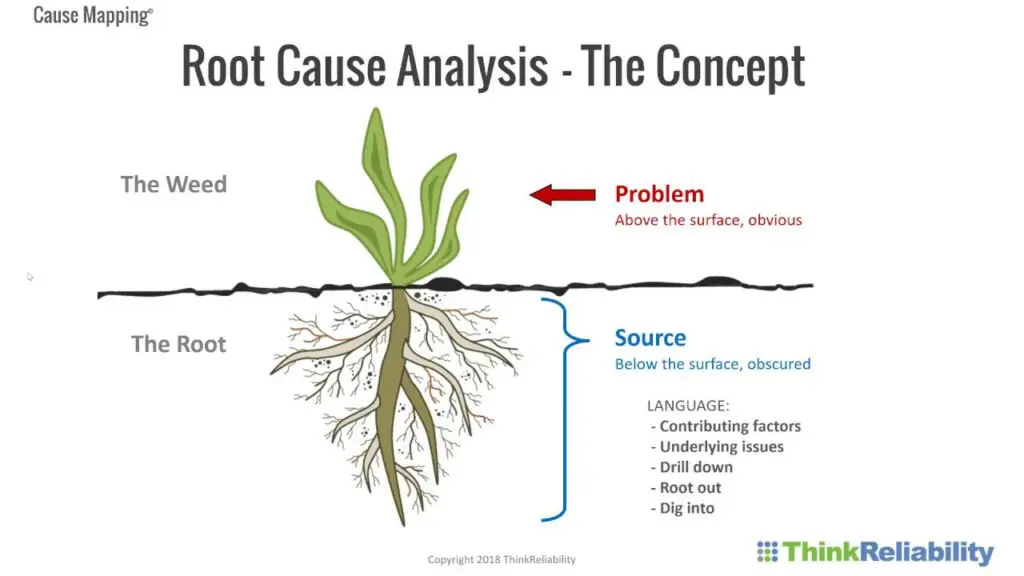

CES has completed number of Root Cause Analysis & Repair Work for the valued clients

In the field of science and engineering, root cause analysis (RCA) is a method of problem solving used for identifying the root causes of faults or problems.[1] It is widely used in IT operations, manufacturing, telecommunications, industrial process control, accident analysis (e.g., in aviation,[2] rail transport, or nuclear plants), medicine (for medical diagnosis), healthcare industry (e.g., for epidemiology), etc. Root cause analysis is a form of inductive (first create a theory [root] based on empirical evidence [causes]) and deductive (test the theory [underlying causal mechanisms] with empirical data) inference. RCA can be decomposed into four steps: Identify and describe the problem clearly Establish a timeline from the normal situation until the problem occurs Distinguish between the root cause and other causal factors (e.g., using event correlation) Establish a causal graph between the root cause and the problem RCA generally serves as input to a remediation process whereby corrective actions are taken to prevent the problem from recurring. The name of this process varies from one application domain to another. According to ISO/IEC 31010, RCA may include the techniques Five whys, Failure mode and effects analysis (FMEA), Fault tree analysis, Ishikawa diagram, and Pareto analysis.

Environmental Protection is achieved by means of:

The major challenge facing the power generation industry over the coming decades will be to increase the efficiencies of fossil-fuelled power plants while meeting increasingly stringent environmental goals. In particular, there is a need to reduce the emissions of CO2 to the atmosphere, with near-to-zero CO2 emissions being the ultimate goal. Intensive research and development (R&D) is ongoing to develop and commercialise technologies for carbon capture and storage (CCS). For PCC and CFBC boilers, oxy-fuel combustion systems that produce high purity CO2 exhaust streams ready for carbon capture are under development. Oxy-fuel combustion is based on existing boiler technologies with addition of compression and separation processes that already exist in other industries and that have only to be adapted and scaled-up to power generation application. Oxy-CFB technology may have some advantages over oxy-PC combustion designs. When oxy-fuel combustion is applied to a CFBC boiler, the combustion temperature can be controlled by recycling a portion of the cooled solids to the furnace through a fluidised-bed heat exchanger, therefore minimal flue gas recirculation is required. This characteristic allows the oxy-CFB boiler to be made smaller and less expensive in a new unit application.

A power generation technology based on oxy-CFB with CO2 capture will provide typical benefits of CFBC boilers, in particular the fuel flexibility. The ability to fire low grade coals or cofire waste fuels reduce dependence on expensive high rank imported coal, and thus reduces the cost of electricity. In addition, higher O2 concentrations in the combustion gas are expected to increase combustion efficiency and will reduce the flue gas flow rates and thus increase the boiler efficiency. Smaller furnace volumes may reduce costs of the boiler island. Initial commercial designs will likely have dual capability to operate in either oxy-firing or air-firing mode. This will provide a high degree of flexibility and reduce risk to the plant owner from the implementation of the first of a kind oxygen-firing technology.